Consultant Ray Samp of Agari Culture Mushroom Consulting Services and longtime author for Mushroom Business compares the Dutch way of growing Agaricus with the American model. In his view, both systems have their strengths and weaknesses.

INTRODUCTION

I’ve been in the Agaricus mushroom business since 1976, almost 45 years, and during that time I have been grower, manager of growing, farm manager, group farm manager, and for the last 29 years I’ve been technical advisor/consultant to mushrooms farms all over the globe. These farms have been of all sizes, arrangements (shelves, bags, blocks, trays, beds, and bulk phase I/II/III systems), and climates. I’ve been able to advise successfully in all these systems/locations because of my approach to mushroom growing. With an advanced degree in microbiology, I have made it my charge to fully ‘understand’ the biology and processes of mushroom growing so that I could adapt that ‘understanding’ to any type of mushroom farm, in any location.

Over these almost 30 years I have enjoyed the opportunity to work on every system, in many environments, with many raw materials and made it a personal challenge to understand each system in order to prescribed the correct cultural advices to each client. Since I ‘cut my teeth’ in the American system of growing (the first 11 years), I have found it interesting that the ‘American model’ of mushroom growing is different from other parts of the world, particularly Europe. I cannot say the American system is better, in fact in many ways it is inferior to other systems, but it has its strengths and exists as a matter of necessity. Natural selection one might say.

DUTCH TECHNICAL MODEL VERSUS THE AMERICAN TECHNICAL MODEL OF AGARI-CULTURE

Because of my perspectives I’ve been asked to write this paper comparing the 2 growing systems – the US system and the ‘Dutch’ European system of mushroom growing. In general, the US System may be described as: High production/m2, high production efficiency (return on dry matter compost), lesser quality (at times), more labor intensive, grown in wood beds, wood trays, or aluminum shelves on one-zone phase I or phase II compost. In general, the Dutch System applied around the world may be described as: lower production/m2, similar production efficiency (at times lower return on dry matter), more equipment/technology intensive, and higher quality grown mostly in aluminum shelves, but also plastic blocks (and rarely metal trays).

Primarily, the very high yields (US) vs lesser yields (Dutch) are the major differences in the two systems, but there are many secondary differences that cause the differential in production. The US model uses 2 basic compost tenets to achieve the very high yields: very high phase II compost fill weights and a very mature, well converted, less structured, longer cycle phase I compost. The Dutch model uses shorter cycle, less mature, more structured phase I compost, processed in bulk phase II and III for fill at much lower weight on the shelf.

For example, a fully integrated US farm might have a 3 plus-week phase I composting cycle that uses various raw materials. The phase I compost is pasteurized in trays, beds, or tunnels (mostly tunnels these days), moderately supplemented (~0.8-1%) and then filled onto beds or shelves at ~125-130 kg/m2 (26.6-26.7 lbs./ft2). Wood tray fill is generally a bit lighter. This will grow the farm ~37-43 kg/m2 (7.6-8.8 lbs./ft2) of 95+% closed cup mushrooms in 3 flushes. A Dutch system might use a compost that is made of straw (or stable bedding), gypsum, and poultry manure handled for 7-14 days, processed in bulk phase II/III tunnels, supplemented heavily (1-1.6%) and then filled onto shelves at ~85-90 kg/m2 (17.4-18.4 lbs./ft2). This farm will grow 25-33 kg/m2 (5.1-6.75 lbs./ft2).

Given those general characteristics of the two systems, why does each do what it does? Why has each system taken the approach they have? Actually, this is simple but very complex at the same time. Each system does what it does for market reasons. Over the years, the US market has been very tight, with profit margins very narrow. This is in part because the multiple chains either dictate prices and/or make each farm bid against each other to gain sales. This has put constant downward pressure on pricing over the years. Meanwhile, operating costs continue to increase. Raw materials, labor, energy, etc. costs increase almost every year, so between the price and cost squeeze, there is a viability challenge. Financial break even on most farms is over 35 kg/m2 (7.16 lb./ft2). As such, with a fixed asset (same amount of m2 of production area), the only way to increase revenue is by growing more mushrooms per unit area. So, over the years the approach to cover increasing costs and maintaining profit levels has been to increase yields/m2. In my career average production per meter squared has risen from ~15 kg/m2 to 40+ kg m2 (~3 to 8.3 lbs./ft2)!

Because of the high production requirements, quality standards are not as high as European system farms. Mind you, quality is not bad, it is just not as good as some Dutch system farms. The reality is, quality may gain the sale if there is a tie in the bid price, but does not gain enough revenue to justify lower yields to grow that quality. In the US system the objective is to maximize yields with enough quality to compete with other US (and Canadian) farms. In other words, the farms operate on a ‘quantity preferred’ basis. Mind you, quality is still good, just not superior. For perspective, US farms would grow ~5-10% cannery grade or opens within that 40+ kg/m2 total to avoid low price average.

In Dutch model dominant markets, markets are still tight, but apparently not as tight as the US. For example, I know of no US farm that would break-even financially at 32 kg/m2 (6.5 lbs./ft2). Financial break-even yields at some farms can be as high as 38 kg/m2 (7.75 lbs./ft2) — particularly those who have invested in systems and technology. (That is why there are still so many archaic farms in the US. Investing into assets is costly and yields questionable returns. A return of better quality only is NOT viable.)

Back to the matter at hand, Dutch system dominant areas have had enough profit margins that 30 kg/m2 will easily keep the farm afloat (32 kg/m2 in Holland). As a result, it is at that level that growers aspire to. I have understood that the reason Dutch system growers have not taken the US approach to increasing revenue (more yields) via increased compost on the shelves is that >90 kg/m2 phase III compost actually reduces yields. As a result, Dutch system farms compete on quality with as much yield as they can get. In other words, farms operate on a ‘quality preferred’ basis.

Beyond that, Dutch system areas are heavily capitalized and planned around cost, space requirements, and maybe government assistance. Because Europe has much less space than US, is more environmentally conscious, sourcing labor is more difficult, and more energy conscious, European farms operate with much smaller footprints, are more capital intensive, and are more efficient with respect to almost all operations. Short phase I cycles and bulk phase II/III certainly adhere to that point, whereas the US farms usually occupy much more space, use more labor, are under-capitalized, and use old, ugly equipment. Pennsylvania doubles are archaic.

Additionally, until recently anyway, in the US cheap labor has been easy to source. As such, whenever a problem relating to yields can be solved by adding labor – we do it. Again, because yields is KING. Adding a small cost to gain yields is an easy calculation. Not so in Europe where a REAL cost:gain analysis must be made before adding labor.

“WHY DO YOU DO WHAT YOU DO?”

So, these are the general differences between the US system and the Dutch system, but beyond that, the question that is frequently asked of me abroad is, “why do you do what you to and not go to the obviously superior Dutch system”? Equally there are those in the US that ask me, “why do THEY do what they do since we could not be in business with that capital expense and lower yields”? My answer to both of those questions is the same, ‘there are horses for courses”, which means both are systems which have evolved under the financial environments in which they operate. Each system, and I may say strategy, is correct for where they are. Geographically, the US system is somewhat limited to the US, and the Dutch system is dominant for Europe, but is also used in most countries around the world. Having said that, I believe most of the mushroom growing world could benefit from some of the characteristics of the US system.

In my line of work, I advise on cultural techniques and strategies for optimization of any mushroom farm in any location. I’ve worked on all continents, with many combinations of systems, and have had several clients with bulk phase III/shelf systems. Given that, I advise my US clients that the best system for the US is a hybrid system, where we can meet our yield objectives with better, more efficient operating systems. In my view, bunkers, phase II tunnels, and shelves are great. Everyone should have them, but to this date bulk phase III is not for the US. There have been several state-of-the-art, greenfield site, Dutch system farms constructed in the US over the decades and NONE of them has succeeded. In fact, almost all of them are gone from the face of the earth. Why? They couldn’t grow the necessary volumes to pay for operations and debt. It should be an easy calculation, but I still see people making that simple mistake. Building a ‘pure’ Dutch system in the US has been disastrous.

For my US clients (and some others abroad), I recommend a hybrid system that takes the best of each system to satisfy an on-going business model. That is, hybrid phase I, bulk phase II, and phase III and growing on shelves. A system such as this allows a more mature, broken down compost, that has proven to be easily processed in phase II tunnels, and then filled at desired weight on the shelves. That gives US farms the ability to process the compost more efficiently and still achieve the desired high yields.

But what about the cost advantage of performing phase III in tunnels? I have done a detailed capital and operating cost analysis with some of my clients of phase III on shelves (with more rooms and one more operation, etc.) vs. phase III in bulk and shelf fill/case at the same time. The result was there was a slight advantage to bulk phase III, but not nearly enough to accept lower production potential that cannot be guaranteed with tunnel phase III. Decision made!

CRUNCH TIME

Now comes the crunch! To what can we attribute the production potential of the two systems? If 100% efficiency of mushrooms grown on any amount on dry matter compost is very good, and each system can achieve that, how do the two systems go about achieving it? And what limits one or the other? In my observations over the decades it all comes down to quality of compost and how it is utilized. And by quality of compost, I mean how it is made.

The need to get a high volume of compost in a limited space, at least in part, selects for a mature, less structured phase II compost. Therefore, the US industry has moved in that direction, but in addition to the ability to compact high amounts of compost in a limited space, mature compost has been shown to be more productive. I personally discovered this in 1981 (really) and have rode this discovery to sustained success for my entire career. So by composting the straw, sometimes hay (in Pennsylvania) to a soft, more broken down condition, the US industry can not only achieve high weights/m2, but also enjoy the higher level of production that a mature compost offers. How mature, how short? Well, that is for me to know.

To reinforce that point, let me use this aside. In early 2018 I was handed the largest composter in the western hemisphere to ‘sort out’ because continued poor advice, performance, and yields at the associated farms had left several operations on the brink of disaster. I culturally managed the operation for one year to get the farms (and by association the compost site) solvent. I used the template of more mature compost, critically managed (fully Converted), and higher weights at the farms and all came right. The farms have been riding a wave of success ever since. Let’s just say more decomposition is good.

However, being able to enjoy the advantages of high weights on the shelf and mature compost does not come easy. In order to use compost in this way the compost must be very well managed. Proper formulation, moisture management, aeration, handling, and evaluations over the extended time required to achieve the proper degree of decomposition is essential. If all these variables are managed properly the finished compost can be delivered to phase II Completely Converted. If Complete Conversion is accomplished, phase II and phase III will handle with ease and pinning will follow in kind (although more heat than normal at anastomosis of mycelium in phase III). The 0.8-1% supplementation will not be a problem to control during phase III on beds/shelves. However, if phase I Conversion is not complete, spot heat-ups will occur in phase III, and pinning will be variable with unproductive areas.

On the flip side, the European Dutch system takes a completely different approach to composting. The composting cycle is generally much shorter because of space and environmental constraints. Even considering that most Dutch compost is based on stable bedding, the finished phase I material is still much less mature or ‘greener’ than its US counterpart. It is said that the compost must be ‘greener’ because ‘structure’ is very important in bulk phase III. I do not know that for certain because I have never seen a typical short, mature US type compost put through a bulk phase III. (That is one reason why the US has generally not taken to the bulk phase III systems – and that I advise clients against it because it has never been proved and provides little benefit.)

Additionally, European Dutch style phase I compost is usually formulated low in nitrogen and incompletely converted. I believe it is formulated low so it is easier to convert most of the nitrogen within the short phase I cycle. The incomplete conversion is then accommodated by unsupplemented phase III and low weight on the shelf. I’ll give an example of incompletely converted compost by what I’ve seen in Holland.

I’ve visited multiple Dutch compost operations and have closely inspected the finished phase I product. I’ve seen variably composted straw, some free incompletely converted poultry manure, and horse droppings in varying degrees. The amount of each has varied depending on the time of visit, the compost site, and duration of the cycle. My manner of inspection is notoriously thorough and after inspection have been asked by my tour guides or managers, ‘what do you think?’ As diplomatically as I can (quite unlike our last president) I’ve responded. “This would NEVER work in our system.” It may, and does work in the ‘Dutch” model, but I KNOW that that compost would result in excessive heat-ups in early spawn run (phase III) and poor production in our system. Especially considering we spawn with supplement at high weights/m2 on the shelf. (again 125-130 kg/m2 or 25.6-26.7 lbs./ft2)

In the Dutch system, supplement is added after a complete spawn run under excellent temperature control in the tunnel. At tunnel empty, the fully colonized compost is heavily supplemented (1-1.6%) and filled at only 85-90 kg/m2 (17.4-18.4 lbs./ft2). Although there is significant heat after casing, it can be controlled by heavy watering, the light shelf fill, and because of the high surface area to volume ratio that the compost has on the shelf. Because of this physical situation the compost temperature can be controlled much better.

I would think the reason higher weights haven’t produced to justify the added compost is because the surface area to volume ratio is less optimum and the heat from the incompletely converted compost affects pinning, resulting in lower or equal yields over time. This situation can also occur on an incompletely colonized bulk phase III compost (when the bulk phase III duration is 13 days or less).

In essence, the 85-90 kg/m2 shelf fill is augmented by nearly 50% more supplement than the US system uses. This higher supplementation rate compensates for the lower N formulation in phase I and the lesser phase I conversion. At times I’ve thought of this strategy as piling loads of fertilizer on an unfertile soil. (Having said all that, ever since I convinced a former phase III client in Australia to extend their phase I composting cycle, they have produced consistently higher than other phase III operations, reinforcing the compost maturity assertions.)

So, the Dutch system works, and works well. But as I see it, the limitation of the Dutch system is that it is VERY difficult to increase yields since compost weight on the shelf is very difficult to increase. In that regard the system is limiting. Also, if more composted, less structured material is said to be incompatible with bulk phase III, so yield can only be increased incrementally via that approach. So, the system is stuck where it is.

CONCLUSION, ETC.

In the end, which system is better? The answer, ‘horses for courses’. Both systems are correct for the environment in which they occupy, but in my view the best system for most parts of the world is what I mentioned earlier. Taking the strengths of each system and applying it with a hybrid phase I and tunnel II with phase III, pinning, and cropping on shelves. In this way a farm can benefit from the strengths of each of the two systems.

ADDENDUM — I’m sure at this point those aware of the state of the international mushroom industry and operate Dutch systems would say, ‘then why does the Canadian mushroom industry, with Dutch systems, compete so well in the US”. Of course, that is the logical next question. Those of you who are familiar with the international industry are also acutely aware of the benefits of favorable currency exchanges. I remember when I worked South Africa for many years that they were more aware of monetary markets that I will ever be. Why? Because of the cost of imported raw materials. Ireland was also acutely aware of currency markets when Britain was using the pound sterling (the first time).

The fact is, Canadian mushroom growers enjoy a significant currency advantage to US growers. That allows them to export into US markets, where the high quality they grow with their Dutch strategy competes well with US quality. When one grower enjoys a 12-15% price per kg of mushrooms premium there is no reason he has to work so hard and source/manage more pickers to obtain high yields to run his business. (Currently exchange rate is 21%, but an estimated 12-15% is the actual benefit.) Growing 30 kg/m2 (6.1 lbs./ft2) is enough to keep a qualitative advantage, which gains them the 12-15% currency advantage. Nice.

And speaking of quality, why is Canadian quality better? Fundamentally it all goes back to yield expectations and subsequent crowding of mushrooms on the casing. I created and have been using a ‘pin counter’ since 1985. Really. It allows me to evaluate a pinset and predict the quality and quantity days before harvest of any flush. With that experienced perspective, the typical good quality US farm would have ~12-14 mature pins/100 cm2 (16 in2) area. A poorer quality farm would have ~15-18+/square. When I worked in Australia, UK, Ireland, and other high-quality industries, my target was ~5-8 mature pins/ 100 cm2 square. End point, quality is MUCH better when there are half the mushrooms/unit area. Expectations of 30 kg/m2 vs 40 kg/m2 (6.1 vs 8.2 lbs./ft2) allows that.

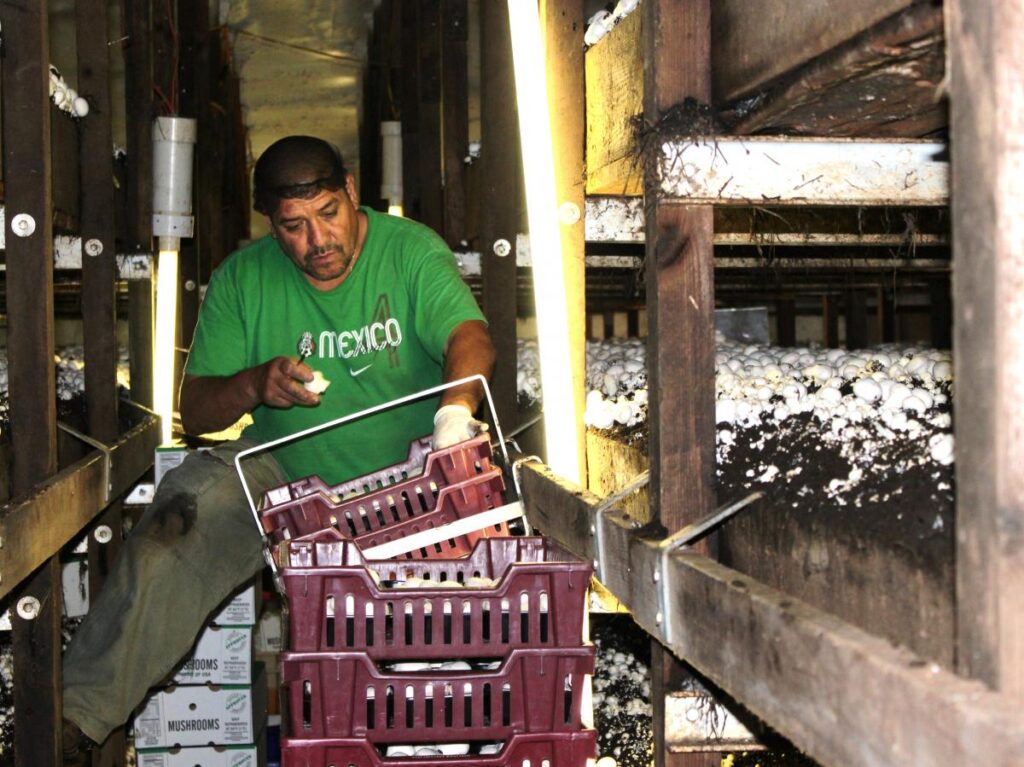

Photo: Traditional mushroom growing at To-Jo in the USA in 2011. Photo: John Peeters for Mushroom Business.

This article was first published by Champfood.